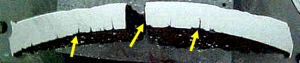

There is no effective commercial device/procedure for detecting internal cracks in boiler tubes. They often accompany welded “fins” on the tubes. They can be isolated or multiple cracks.

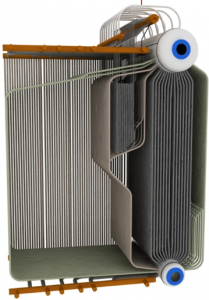

These cracks occur along the “fins”, both in straight sections and in curves, and frequently in places that do not allow access for “direct” inspection by ultrasound, such as in regions of “explosion beams”, and “supports”. The case is simpler when the inspection can be “direct”, but it is significantly more difficult when the inspection has to be done from the “opposite side”, due to lack or difficulty of access for the “direct inspection”.

br> In this case the inspection has to be done from the opposite side, that’s where the “CRACKED_TUBE_SCANER” comes in, specially designed for this case.

The sonic beam designed for each case is projected through the fillet weld of the fin by a special shoe.

ARAUJO Eng./ MVA Inspection, developed, manufactured and qualified the inspection procedures according to ASNT and SNQC, and successfully applied them in field inspections. Initially to address a specific customer problem, it is now available for service throughout Brazil and abroad.

The “CRACKED_TUBE_SCANER” is a tested and qualified product for detecting cracks in boiler tubes.