IRIS

INSPECTION OF HEAT EXCHANGER TUBES AND BOILERS

Examination of tubes by the IRIS technique (Internal Rotary Inspection System) can be applied to any material such as carbon steel, stainless steel, copper alloys, nickel, aluminum, and even non-metallic materials.

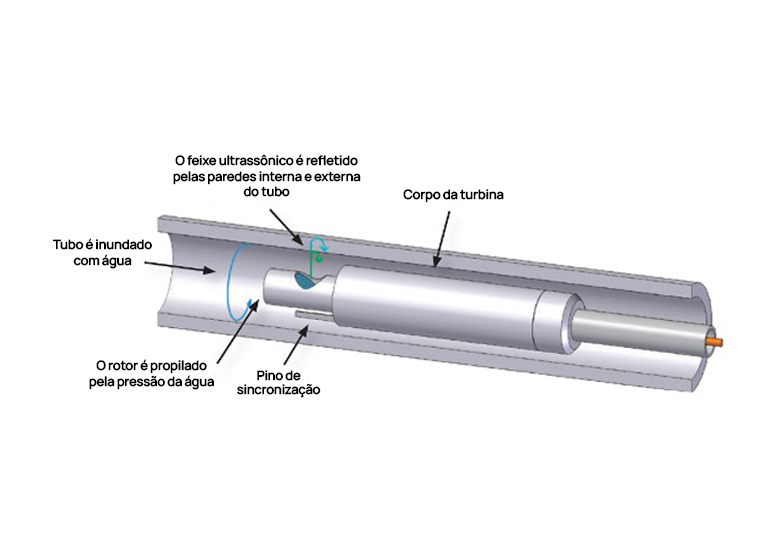

It is a technique of the ultrasonic method, which basically consists of “scanning” the entire length of the tube by a normal ultrasound beam. This is done by rotating a small mirror coupled to a turbine powered by water that receives the beam and directs it perpendicularly to the surface of the tube, as shown in the figure below, the water is also used for coupling.

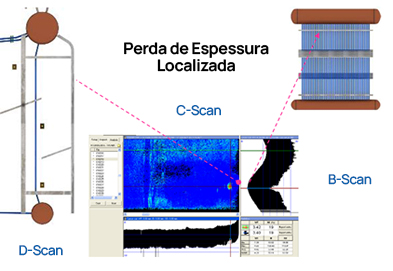

Our technology allows the precise location and dimensioning of worn areas and points, through the B/C/D-Scan features. These resources are available “online”, to provide information necessary for immediate decision making, and are also recorded for later analysis and reporting.

The results obtained in this way are presented as illustrated below, which allows the precise location and dimensioning of the damage.

We use modern equipment, with software and up-to-date technology, such as the “Eddyfi Ectane and the Olympus MS 5800″ with features such as C-SCAN-ID-VIEW, and C-SCAN-OD-VIEW, which are essential when one of the surfaces ( internal or external) of the tubes does not allow adequate sound reflection, as in the case of finned tubes or heavily corroded surfaces.

MAIN ADVANTAGES

MAIN DISADVANTAGES

– Rigorous cleaning requirement;

– Low test speed (typically 600 linear meters per day);

– Only detects loss of thickness damage;

SOME OF OUR DIFFERENTIALS

- Supervision by a multidisciplinary engineering team with experience in equipment inspection and maintenance. Vast collection of records of the various types of damage that occur in tubes of heat exchangers and boilers;

- Simultaneous and real-time B and C-SCAN inspection, which provides greater accuracy for the detection, location and dimensioning of discontinuities;

- 100% recorded inspection, the data can be re-evaluated at any time, or even be compared in future inspections;

- Work procedure with immediate analysis of data in the field, or simultaneous collection and analysis, this last resource allows optimizing the effective working time in the field;

- B/C/D-Scan data analysis;

- Data recording in 3D sketch;

- Inspection Statistics;

- Inspection capabilities only for inner or outer tube thickness;

- Qualified professional according to SNQC – ISO 9712;

- Professional SNQC Level III in own ultrasound;

- Possibility of applying simultaneous electromagnetic techniques (EC, RFT, MFL) to complement and increase the effectiveness of the inspection;

- Inspection of pipes with a diameter from 9.5mm to 101.6mm;

- We can develop devices for specific applications.