EC-mfl

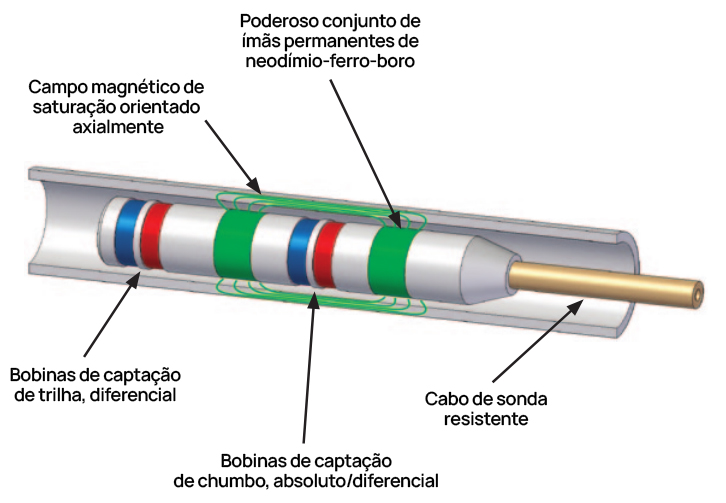

It is an electromagnetic method technique, which consists of “scanning” the entire length of the tube using a probe built with two strong permanent magnets. These magnets generate a magnetic field that saturates the tube wall.

An absolute probe measures the variation in the magnetic field caused by thickness losses.

When a fault is located between the two magnets, a “disturbance” in the magnetic field occurs resulting in the “leakage” of a small amount of magnetic flux into the internal diameter of the tube.

This flux is detected by a differential coil, located between the magnets. A winding placed at the end of the probe detects residual magnetism and allows discrimination between internal and external damage.

An absolute probe measures the variation in the magnetic field caused by thickness losses.

When a fault is located between the two magnets, a “disturbance” in the magnetic field occurs resulting in the “leakage” of a small amount of magnetic flux into the internal diameter of the tube.

This flux is detected by a differential coil, located between the magnets. A winding placed at the end of the probe detects residual magnetism and allows discrimination between internal and external damage.

MAIN ADVANTAGES

– Inspection of finned tubes;

– Allows the inspection of partially encrusted tubes;

– Detects pits, circumferential cracks and loss of thickness;

– It is not very sensitive to the presence of baffles and mirrors;

– Allows high data acquisition speeds;

– The interpretation of the results is relatively simple.

MAIN DISADVANTAGES

– Sizing is precarious, it is mainly recommended for damage detection;

– Required fill factor is similar to eddy-current;

– Requires the fabrication of standards for each type of pipe examined.