EDDY CURRENT ARRAY

Examination of welds and plates by “Eddy-current” for the detection and dimensioning of cracks, through the use of special equipment and probes, according to the EN1711 standard “Non-destructive examination of welds – Eddy current examination of welds by complex plane analysis” and ASME V Article 8 Eddy Current Examination of Tubular Products;

MAIN ADVANTAGES

– Less demanding surface preparation;

– Does not require paint removal;

– Does not require consumables;

– Does not require utilities (water, energy or compressed air);

– No filter required;

– Fast, clean and effective process;

– Faster than magnetic particles and liquid penetrant;

– Allows recording of calibration and inspection, and consequently the monitoring of the evolution of discontinuities;

– Advantages under the ACFM / Liquid Penetrant and Magnetic Particle tests (see additional documents “ACFM x EC” and “EC x PM_LP”);

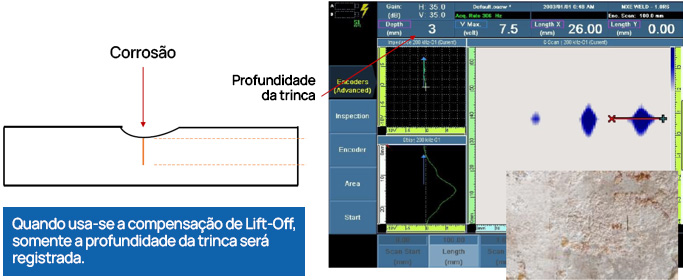

– Eliminates noise caused by corrosion;

– High POD (Probability of Detection);

– Minimal analysis is required with real-time records;

– It is possible to measure the depth of discontinuities.

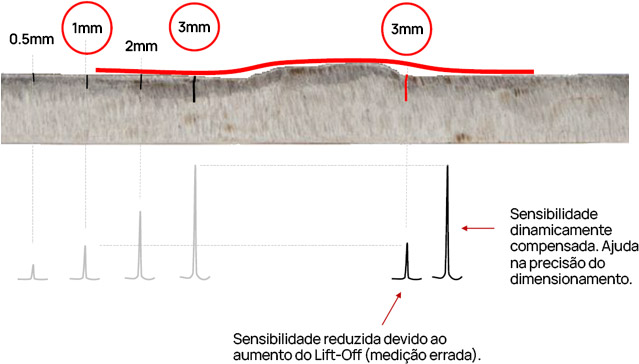

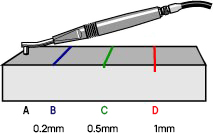

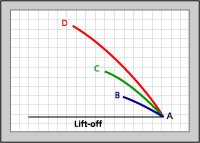

LIFT OFF COMPENSATION

Lift Off compensation helps to reliably measure the depth of discontinuities:

– For welds;

– Corroded surfaces;

– Painted surfaces;

– Stress corrosion;