pec/peca

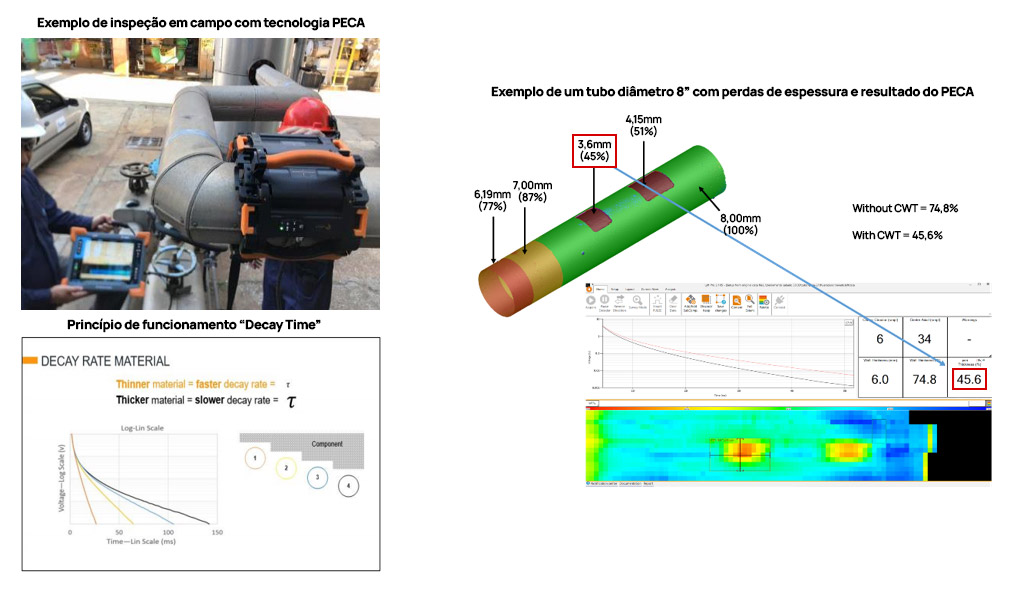

Pulsed Eddy Current, or PEC, is an electromagnetic inspection technology used to detect thickness loss in ferrous materials (Low carbon magnetic steels, ferritic and martensitic) hidden or not under layers of coating, fire protection or insulation thermal. The technique allows the measurement of wall thickness without the necessary direct contact of the probe with the surface to be inspected, being a screening tool and providing relative thickness measurement.

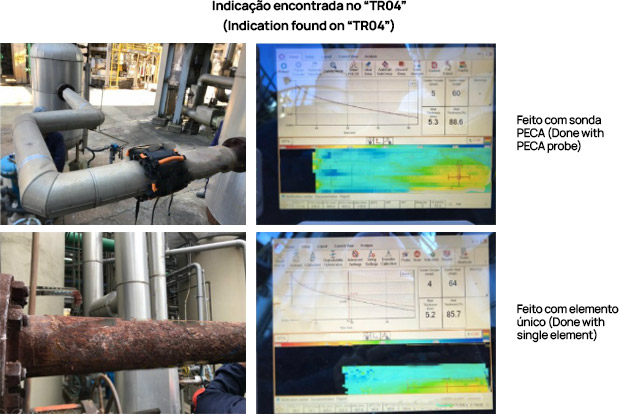

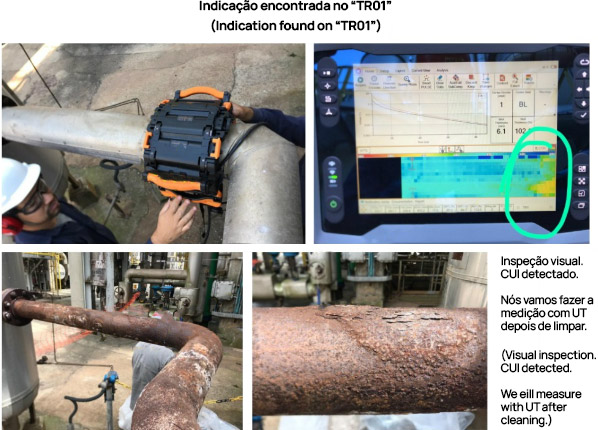

Figure 2 – Example of pipes with thermal insulation. It was examined by Araujo Engenharia using the PECA technique. In sections where insulation removal was recommended, thickness losses were confirmed.

PEC – Pulsed Eddy Current

PEC-type probes are used, without array technology, in grid mode (point measurement) or dynamic mode (scan measurement).

PECA – Pulsed Eddy Current Array

Probes and array technology are used, which ensure greater productivity and sizing accuracy. The probes are large and can be adjusted for tubular or planar surfaces.

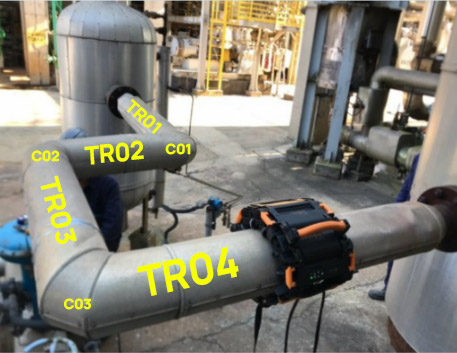

PEC + PECA – Pulsed Eddy Current Array

Conjugation of two techniques. In a pipeline, for example, it is not always possible to use only the PECA technology, as the curves will have limitations for probe coupling, in which case the probes/PEC technology is used as a complement.